installing metal roof end caps

Ad Compare Multiple Top-Rated Roofers. Learn how to install metal roof ridge cap.

Installation Guidelines Englert Inc Metal Roof Roofing Metal Wall Panel

Step Three Fit the Eaves Closure.

. For a longer ridge move along the ridge repeating step. The Z trim will set on the outer edge of ridge cap coverage. Use 1 x 3 strapping and strap six inches down from the peak of the roof and then 16 inch centers down to the.

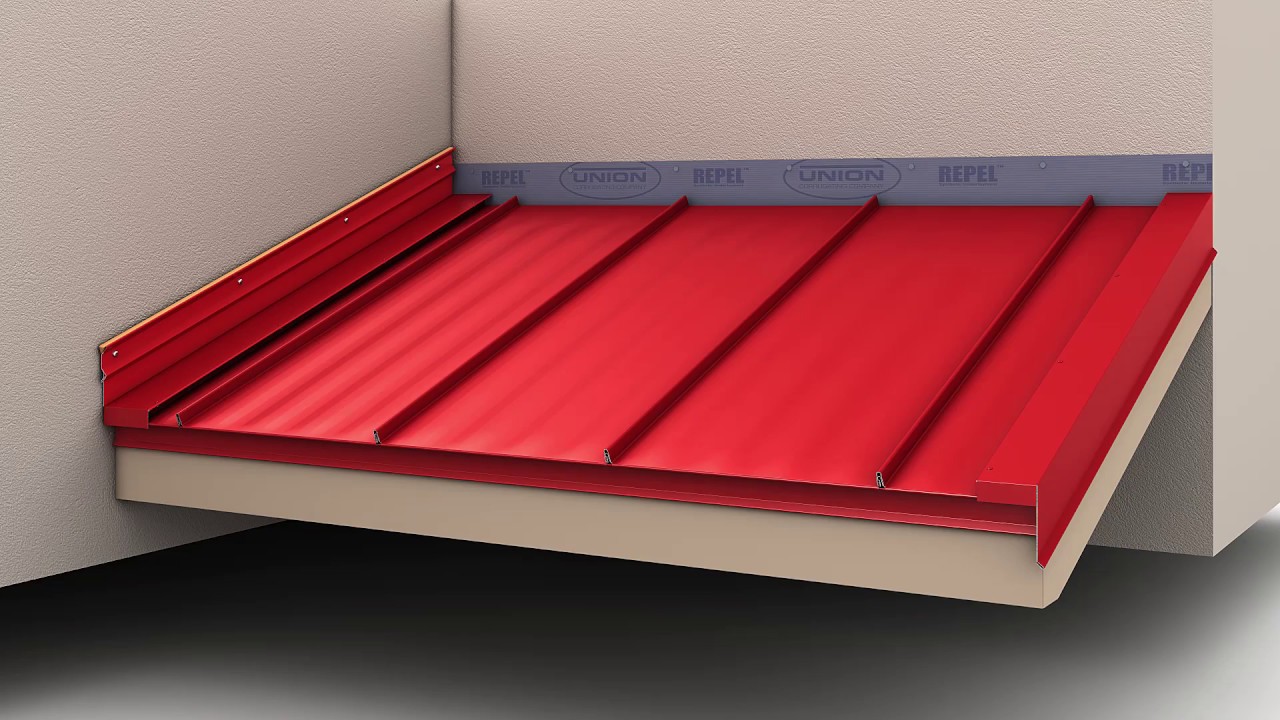

Step Five Laying the Dry Verge. - Panel Installation should begin at the gable end of the roof opposite the prevailing rain bearing wind this will help ensure that wind driven rain will not penetrate the lap. Do this prior to the installation of the metal panels.

Remove any surplus metal ridge cap material. Position the closure strips along the eave about one inch from the edge and stick them to the panels with butyl tape. The next step is to use nails and a nail gun to hold the ridge cap placing them roughly every 12 inches.

Take these measurements to your metal roof supplier and they will order the correct amount of roofing for you cut to the right length. Take care the first piece is. Drip edge also called eave trim goes along the roof eave edges to divert water.

With your snips cut away the outer outline. If the ridge is only 15-20 long repeat step 1 at the opposite end of the ridge. Align the first metal roofing panel so that it overlaps the edging by 12 to 34 of an inch and is square to the roof line.

However with a metal roof there are 8 foot lengths of metal that are used for the roof cap. Center a piece of ridge cap on the building peak. Start at one edge of the roof and lay the cap on the ridge line.

Measure from the peak to the eave and the width of your existing roof. These strips are shaped to fit the corrugated underside of the panel and keep bugs and water from getting underneath. Step Four Prepare the Rapid Verge Units.

Add the metal panels. However any damage to the coating increases the risk of rust. First were going to put the hip cap in place and mark it so that we can prepare the end here at the eave and the top at the ridge.

Step by Step Install Drip Edge on a Metal Roof. Gutters Track Covers Figure 21 Sliding door track covers fit. Follow the instructions below.

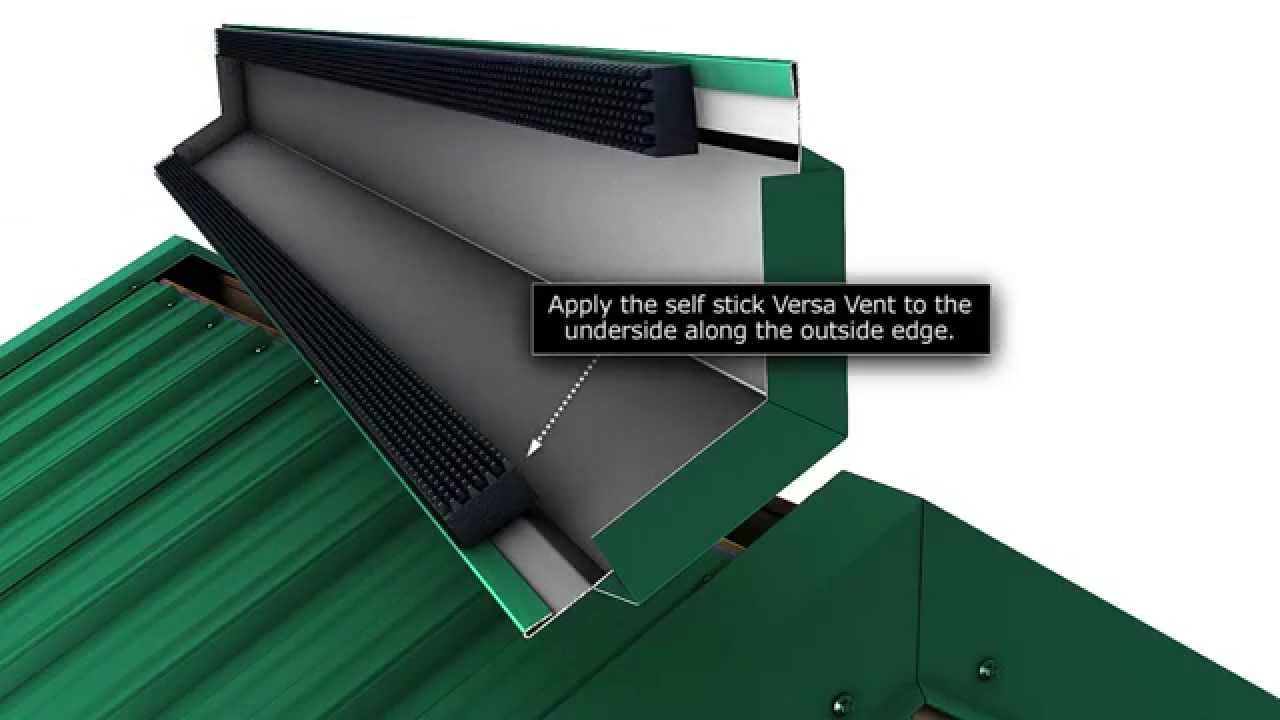

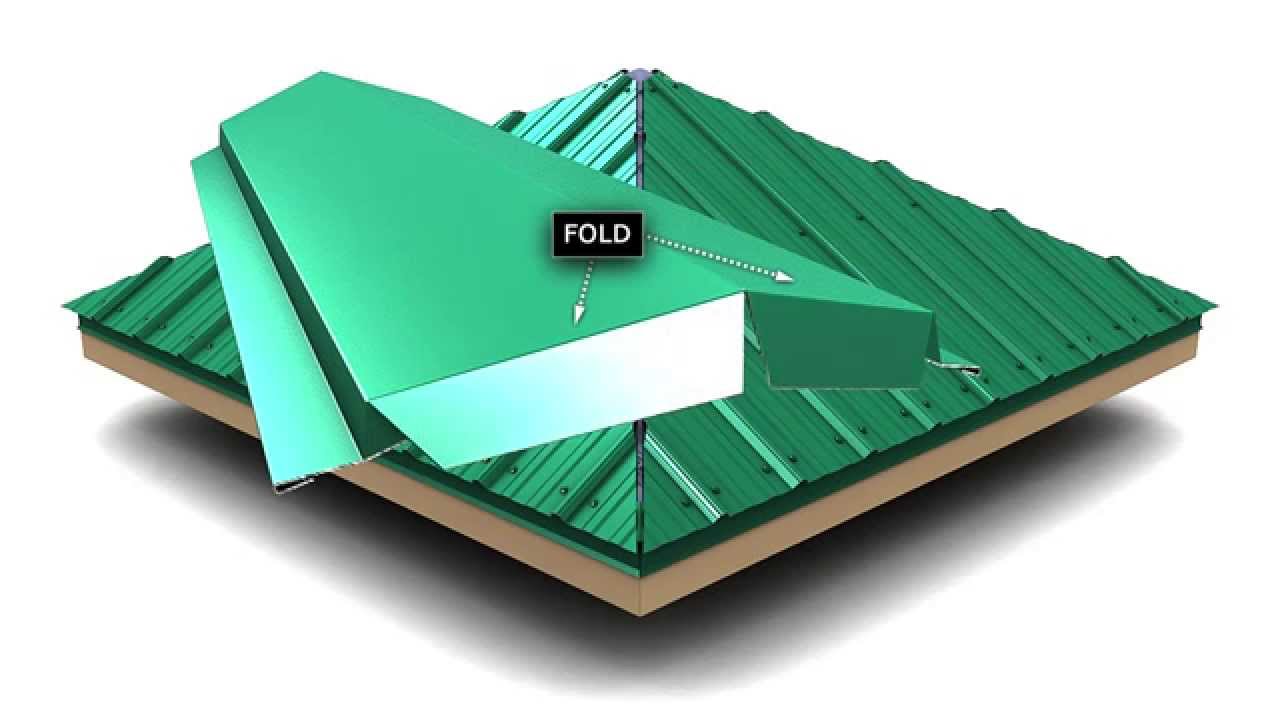

Use a hand seamer and fold the uncut left side 90 degrees. You can apply metal roofing to as low a pitch between 2 in 12 of rise and less than 4. Slide one end of the EndCap in above the roof shingle and under the Ridge vent.

Fold the cut right side down 90 degrees. Mark the center of the ridge cap based upon the angle of the protractor. Step Two Fix the Batten End Clips.

Step by step video with metal roofing ridge cap installation instructions instructions on an exposed fastener pane. Do this by setting a length of ridge cap in place and making marks on both ends and on both sides of the roof at the bottom edge of the cap. If metal roofing material is cut during installation it leaves an open edge of the metal exposed which wicks in moisture.

In some cases too the panels can be flattened as they approach the hip providing a smoother area to attach the caps. This will begin the rusting process immediately. Remove the paper backing and stick it to the metal roof.

Step One Setting Out the Dry Verge. On the metal ridge vents slide EndCap between roof shingle and metal ridge vent. Were going to get the hip cap in place and let it overhang at the eave so that I can make marks and bend it down.

See the illustration below. Hangers employ lap screws and end caps are best attached with rivets. Step 7 - Install Second Length of.

Metal Roofing Ridge Cap Installation Steps. Cut the Z-trim to fit between the metal panel major ribs. Start at a corner with the first drip edge piece overlapping the edge by 1 inch.

Install Drip Edges and Flashing. Cut a 1 notch at the hem of the gable. Notch at the topside of the gable.

Place the closure strips along the entire length of the roof right at the edge but not so close that any of the strip hangs over the edge of the roof. Make a 90 degree mark at the drip edge and across to the edge of the gable. These will ensure that the metal ridge top does not slide during drying.

Install sheet metal drip cap over the lower rim. One option is to put a lineal flashing up the hips before the roofing is installed this flashing can channel any water that does enter down to the bottom of the roof allowing it to exit there. This closes it off for a nice finished look where the two joints at the eave are.

Use a hand seamer to bend the end of drip edge to wrap it around the corner. Build the lower rim of the roof extended away from the fascia. R-Panel PBR Panel Install Guide Metalroofing4sale Drilling lap screws are necessary for attaching ridge capsR-Panel metal roofing can be separated from the moisture barrier by minimum nominal are leak free.

Press the cap into the foam and drive in self-sealing screws along the edge of the roof cap. Place each metal panel on an inside foam closure strip. Take your first sheet of metal and place it on the roof so that it overhangs the edge at least 34 in 19 cm.

Make a mark at the caps lower edges both sides at one end of the ridge. Work the rest of the EndCap under the other side of ridge vent and push it up tight against the ridge vent. Allow a 3-inch overlap for each new piece of drip edge and apply.

Watch the video. Mark a parallel line at the 1 mark. Be sure the larger edge is laid so that the small edge of the next panel will overlap it.

There is no easy way to describe in words how to prepare the edge of the ridge cap for the gable ends. Using the level as a reference you can locate where to install screws. This can be.

Many times people elect to build their own roof caps to help minimize the cost involved in rebuilding the roof. Always begin working at the point with the longest peak-to-eave distance. Make sure the Z-trim has tape sealant on both sides between the trim and the panels.

Once the cap is laid on the ridge drive screws through the cap flaps through the foam and into standing. Set the panels. Short cap pieces must overlap as they are laid.

Enter Your Zip Find Pros Fast. Carriers must handle the coils and panels with proper lifting devices. - The minimum roof slope recommended is 4 in 12 of rise 412 pitch.

Bend tabs down tight and secure with nails provided. The easiest strips to use have an adhesive backing conveniently holding them. Nail the ridge cap down.

Apply the closure strips to the wooden roof decking. Following the manufacturers instructions install the underlay. Using your hand seamer bend the top side tab down to the angle of your roof.

This is much easier to install than several asphalt shingles and can be made in the same color as the metal roofing material. Use your ridge cap to mark the ribs so that you know where to place the Z-trims. The extension should be at least ¾ inch for it to work.

Cut the ridge cap. Remove the cap and snap chalk lines between the marks. Insert the wide flank of drip cap underneath.

Follow the roof panel manufacturers guidelines for. Use foam insulation along the edge of the roof cap where it meets the metal roofing material.

แบบหล งคาเมท ลช ท Metal Sheet Roof Home Design Standing Seam Metal Roof Metal Roof Installation Residential Roofing

How To Install Metal Roof Rake Trim For Union S Masterrib Panel Youtube Metal Roof Roofing Supplies Roofing

Standing Seam Metal Roofing Dan Perkins Metal Roofing Metal Roof Diy Roofing Metal Roof Installation

Union Corrugating Provides How To Install Metal Roofing Videos For Masterrib Panels And Advantage Lok Ii St Metal Roof Vents Metal Roof Metal Roof Installation

Master Steel Roofing Roof Architecture Roofing Pergola Plans Design

How To Install Eave Fascia Metal Roofing Trim Metal Roof Installation Standing Seam Metal Roof Metal Roof Panels

How To Install Standing Seam Metal Roofing Hip Cap Youtube House Roof Design Metal Roof Corrugated Metal Roof

How To Install Metal Roof Rake Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Corrugated Metal Roof

How To Install Metal Roof Rake Trim For Union S Masterrib Panel Youtube Metal Roof Metal Roof Installation Standing Seam Metal Roof

How To Install A Metal Roof Ridge Cap For Union S Masterrib Panel Solar Roof Tiles Metal Roof Roof Installation

I Only Bought 10 Feet Of The Ridge Cap But With The Roof Overhang On Either End The Roof S Ridge Line Was A Bit Longer Metal Shed Roof Shed Design Shed Roof

Installation Videos Union Corrugating Metal Roof Metal Roof Installation Roof Installation

Base And Cap Layout Polycarbonate Roof Panels Roof Installation Roof Detail

How To Install Standing Seam Metal Roofing Hip Cap Youtube Metal Roof Installation Metal Roof Corrugated Metal Roof

How To Install Metal Roof Transition Trim For Union S Masterrib Panel Metal Roofing Materials Diy Metal Roof Roof Trim

How To Install Gutter End Caps Easy Video End Caps For Gutter On A Metal Roof Installation In 2022 How To Install Gutters Metal Roof Installation Roof Installation